The Science of Drying

Why a Desiccant Is Important

The Dry-Brik included with the Dry & Store® family of products has three important functions:

- To remove the moisture molecules released from the devices during the warm drying cycle;

- To drive the relative humidity inside the box to a much lower level than is possible with just a heater, thus maximizing the drying capability;

- To capture odors.

Boxes using heat alone lower the relative humidity by warming the air, but the amount of moisture in the air does not change. While warm air can hold more moisture than cool air, unless the water is removed, it can condense right back where it was when the heat goes off. That’s where the desiccant comes in.

Products without a desiccant might work fine in a desert, but in a humid environment they are simply ineffective. The Dry & Store family of products uses DryMax® technology, with a controlled amount of warm dry air circulating around all of the small ports and openings in an electronic device like a hearing instrument, and the powerful Dry-Brik® desiccant to trap and remove the water molecules from the environment.

Desiccants are essential for an effective drying experience, but it is also important to look at the different types of desiccants to figure out which one is best for keeping moisture out and helping to prolong the life of your hearing device.

The Dry-Brik desiccant is a molecular sieve, which is a much more aggressive desiccant than silica gel. Moreover, mol sieve (pronounced “MOL SIV”) is better suited for the operating temperature of Dry & Store. Silica gel does not work as well as mol sieve at our operating temperatures.

When comparing a molecular sieve desiccant to a silica gel desiccant, at 10% relative humidity, mol sieve can adsorb 15% of its own moisture mass, while silica gel only adsorbs 5%. This means the mol sieve captures more moisture with 3 times less material.

Our Dry-Brik desiccant contain the 13X ranked molecular sieve, which is currently the best. It holds aggressively to the moisture after pulling it from the hearing aid with very strong electrostatic bonding forces. Once the moisture is captured by the desiccant, it cannot settle back on the hearing aid. This is why mol sieve is the preferred method of moisture removal.

The Dry-Brik works to drive the relative humidity inside the unit to a much lower level than is possible with heat alone. It also traps and holds the additional moisture released from hearing instruments. While very effective at drying, the Dry-Brik capacity is not unlimited, and eventually there will be no place for the moisture to go. Replacing the Dry-Brik as directed ensures users will get the most moisture out of the device.

The temperature and corrosion rate are linked. There is a rule in material science that the corrosion rate doubles for every 10°F increase in temperature. Therefore in order to reduce corrosion in a closed system, it’s important to remove the moving water molecules with a desiccant. In addition, body oils and skin acids can be corrosive to hearing aids. The mol sieve desiccant removes grease and solvents by removing both carbon dioxide and water. This protects your products, sealing the ambient environment by a moisture-control desiccant.

The Dry & Store closed systems, along with the Dry-Brik desiccant keep the humidity levels low inside the drying appliance when not operated, which reduces the risk of oxidation. The humidity is reduced by physical adsorption and chemical reaction. Heat and molecular sieve desiccant combine to most effectively break the forces of capillary condensation, which is the hard to remove moisture held in the tiny crevices and pores of the hearing aid. The heat and molecular sieve in the Dry & Store system work together to quickly convert the capillary water condensate into water vapor, which is then swept away by the moving heated air and captured by the molecular sieve.

Some products try to cover up the odors with another scent, but our mol sieve desiccant removes odors. Undesirable odors are caused by molecules of compounds that our senses find unpleasant. Millions of microscopic pores in the desiccant grab some odor molecules nearly as tightly as moisture molecules. The mol sieve even removes airborne ammonia compounds (bacteria) found in sweat. Additionally, mol sieve creates an inhospitable environment for odor-causing bacteria to reproduce.

In summary, the Dry-Brik desiccant, along with heat and moving air, is an effective way to dry hearing devices. This combination pulls moisture from the device, removes odors, pushes relative humidity down, and dries the hearing device to the full drying ability, along with reducing the corrosive factor with increased heat. The Dry-Brik desiccant is needed to help to improve the life of your hearing device, keeping it odorless and moisture-free.

A Real Proactive Drying Strategy

“Moisture is the most common reason for hearing aid malfunction and frustration.”

Beltone™ recently announced they will be adding Redux professional drying systems to participating Beltone locations across the country. The purpose was to “keep their hearing aids dry so they function their best”. Beltone hearing aids are manufactured by GN Resound Corporation.

“Moisture is the most common reason for hearing aid malfunction and frustration,” said Ruben Zielinski, Redux’s President and Co-founder.

Dr. Dan Schumaier, President of Ear Technology Corporation, realized this many years ago and sought a solution. Ear Technology Corporation has been offering drying and sanitizing systems since the 1990s and is the innovation leader in the market.

“Redux systems do remove moisture from hearing aids. However, the systems are expensive and not designed for home use. Thus, the Beltone approach uses a reactive method to remove moisture from hearing instruments once they have failed, or this approach requires patients to return to an office frequently to reduce failures. Having people return to your office to have moisture removed after their instruments have failed or repeatedly for service is not the epitome of good hearing healthcare,” said Dr. Schumaier.

At Ear Technology Corporation®, we believe a proactive strategy to prevent hearing aid failures is the appropriate action for hearing healthcare. Hearing aid failures due to moisture can be sudden but generally occur slowly. Moisture, which is attracted to the diaphragms in microphones and speakers, causes distortion due to the added mass, causing a reduction in high-frequency amplification. Most hearing aid users need help with high-frequency sounds. Moisture also causes corrosion resulting in switch and other component failures.

Approximately 70% of all hearing aid failures are caused by moisture. Ear Technology’s approach to the number one problem is nightly reduction of moisture with the use of a Dry & Store® product. Dry & Store products are designed to use warm moving air to remove moisture from hearing instruments.

Two types of dryers are available:

- Closed systems: such as Dry & Store Global II and Zephyr utilize warm moving air and a molecular sieve desiccant to capture the moisture once it is released from the instrument.

- Open systems: such as DryDome® and DryBoost UV® for rechargeables. These systems utilize warm moving air with the heat breaking the surface tension of the water molecules in the hearing aid, and the air moves those water molecules to the outside through small openings in the dryer.

Our proactive approach reduces the number of patients returning for repair problems as much as possible and/or repeated visits with recurring charges for drying.

How can moisture be measured?

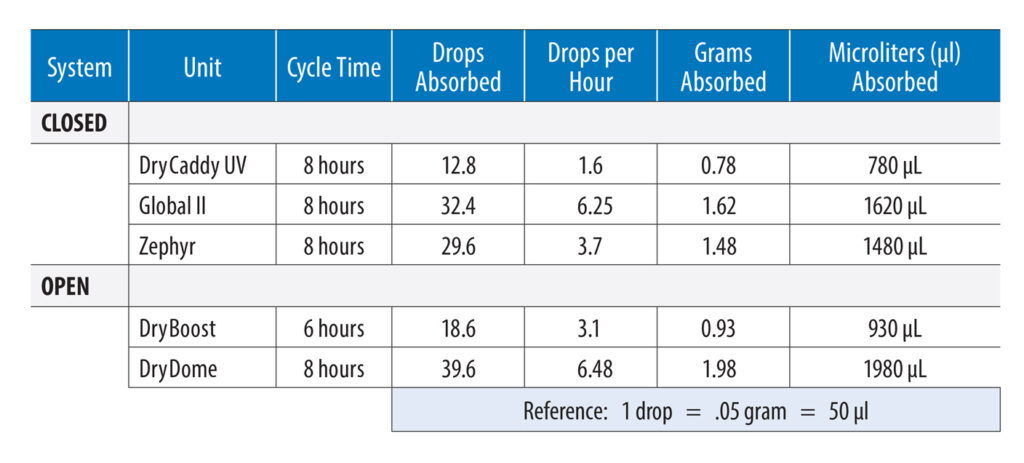

Moisture can be measured in drops, grams or microliters. For your convenience, we have included a comparison chart showing Ear Technology’s closed and open systems’ moisture removal during their cycle times.

Rechargeable hearing aids are also affected by moisture. Therefore, Ear Technology’s DryBoost UV drying system for rechargeables utilizes a lower temperature for drying since temperature can adversely affect the lithium-ion batteries. While DryBoost UV operates at a lower temperature than our other dryers, it still removes 18 drops, 0.93 grams or 930 µl in a single cycle.

We hope this information outlines the importance of providing a drying system for nightly use with every hearing instrument that is dispensed.

A previous survey of 300 Dry & Store users of six months or more, revealed a 2/3 reduction in repairs when a Dry & Store product was used nightly, compared to those using nothing to dry their hearing aids.

Additionally, most Dry & Store products can be customized with your practice name and logo. Also Dry & Store products produce a revenue stream for your business–no costly rentals as with other dryers. Not to mention many Dry & Store units have UV-C lamps for sanitization.